Thanks to many years of experience in all main fields of electrical engineering, we can offer our best support with the realisation of your projects.

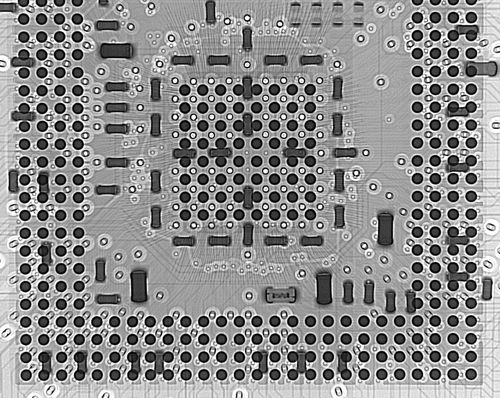

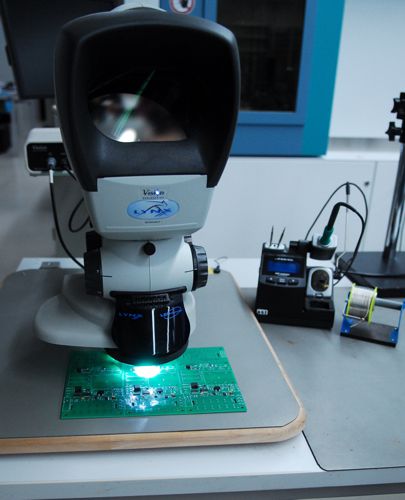

When constructing a prototype, it is important to recognize and eliminate any problems for the following serial production early on. We validate all soldering results from sample production with our x-ray system. This system allows us to check the interior of the soldered joints and even have a look under the BGAs. Each of our prototypes is delivered with its own x-ray report so you can get an idea of the soldering results for yourself. The x-ray results allow us to adapt our soldering processes to your product in the best way possible and thus drastically reduce the failure rate later on.

We take care of material procurement completely, for sample or serial production all the same. We procure material from all over the world and can thus offer you best price and high quality at the same time. Should one of the components of your product be discontinued, we will inform you in sufficient time. We will then also offer a replacement type for the discontinued component or the possibility of a Life-Time-Buy.

These days, there are a lot of requirements when it comes to storing electronic components, such as the MSL (Moisture Sensitivity Level). Many semiconductor components should only be exposed to normal room humidity for a limited amount of time before being processed. Otherwise, fluids inside the component will suddenly evaporate when it is heated up during the soldering process, which can cause damage on the component or even destroy it completely. This is called the popcorn effect. Our especially designed drying storage cabinet and three Juki automatic storage cabinets allow us to not only store these sensitive components properly but also dry components that have already been exposed to moisture. We can thus garantee the durability of your product concerning material failure due to water locks. Our automatic storage cabinets are combined with our production systems. That way we can make sure, that the correct material is handed out from the storage cabinet at the correct point of time.

SMD assembly is the core of every EMS service provider, and we are no exception. Our two ultra-modern highspeed assembly lines consisting of the JUKI FX3, the JUKI 2080 and the JUKI RS1 allow us to assemble your boards with highest precision and perfect quality. Our SMD assembly lines are complemented by a DEK screen printer and a JUKI serigraphy with SPI as well as an ERSA reflow oven. We can ensure a constant level of high quality due to permanent process validation via our x-ray system. After the SMD assembly, each component as well as each soldered joint are automatically checked by a Göpel AOI system.

Tectronic GmbH has numerous ultra-modern, ESD suitable THT assembly stations at its disposal to ensure the reliable production of your devices. With the help of our ERSA wave soldering machine and our ERSA selective soldering machine we can process all sorts of assemblies and achieve the best soldering results possible. Of course, we have experienced staff, who can easily solder your boards by hand, should automatic soldering not be possible for your devices. Our highly trained staff takes care of visually inspecting your electronic devices after soldering. In addition, all THT soldering joints are screened by our x-ray system to ensure the durability of your boards.

We offer several possibilities of testing your devices, from visual inspection to x-ray screening to electrical testing. This way, the high quality of your boards is guaranteed. Visual inspection is carried out by our highly trained staff and our Opticon-AOI. Manually invisible joints and the interior of the soldering joints are checked via x-ray screening. For electrical testing, we offer various possibilities. Firstly, we can program and check your boards via our HP-Incircuit-Tester. Secondly, we have a universal functional tester especially designed for our production. This tester allows us to program and electrically test all of your electronic devices. Furthermore, our test system records all of your devices' test results, which ensures traceability once again. In addition, Tectronic GmbH has a well equipped test field, which enables us to realize all of your inspection tasks. In order to recognize possible failures prior to delivery, we also have the possiblity to temper your boards.

Nowadays, many electronic devices have to function under extreme conditions, which is why we offer to cout and mold your electronic boards. We can therefore guarantee that the electronics will function even in the most difficult conditions. Our ultra-modern coating line allows us to carry out the whole coating process fully automatically and reproducibly. That way we can ensure a constant level of high quality coating. Moreover, we offer to stick components of a certain size down, to lower the risk of failure due to bumps and vibration.

We will gladly take on the final assembly of your product. In our well equipped assembly area we have the possibility to take on all assembly work. All assembly work is carried out by our specially trained staff. Simultaneously to assembly, we do a final check of your devices. That way we can ensure that your quality requirements are met from incoming goods through to outgoing goods department.

Traceability of your devices becomes more and more important. We offer the possibility to label all of your boards with their own serial number. That way, traceability is guaranteed from the material lot to process releases of each individual production disposition to the test results of electrical testing. This allows you to have an overview over which material lot was used on which device and, of course, over all individual test results at all times.

Quality check plays a significant role for Tectronic GmbH. Our QM system ensures very high quality of your devices' production. Our especially developed incoming goods control system guarantees and reports the quality of your individual components from the moment they enter our building. This makes traceability back to each indivual component possible. Each individual process is checked for conformity at the beginning of each production batch with the help of our AOI and the x-ray system. In addition, our high-precision electrical testing guarantees the quality of your devices.

We also offer high-quality support for your devices. Be it repair or maintenance of your devices - you are right with us.